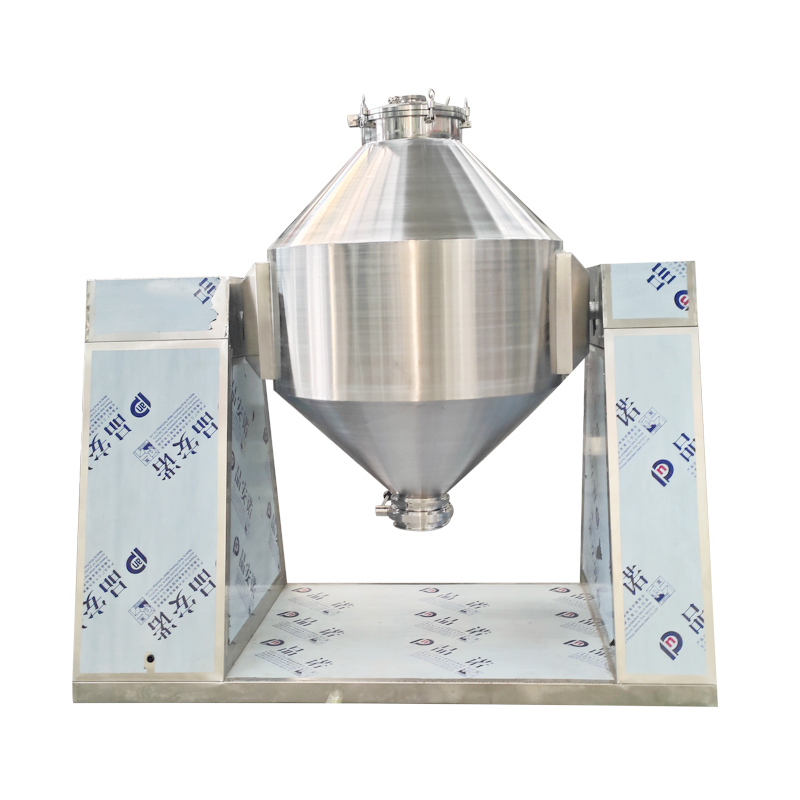

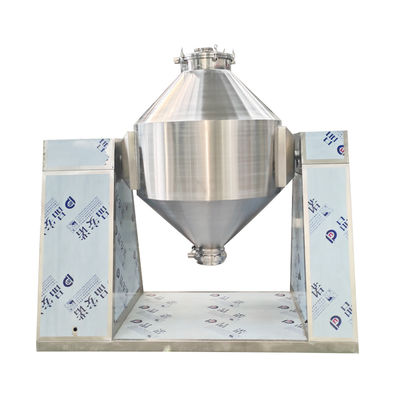

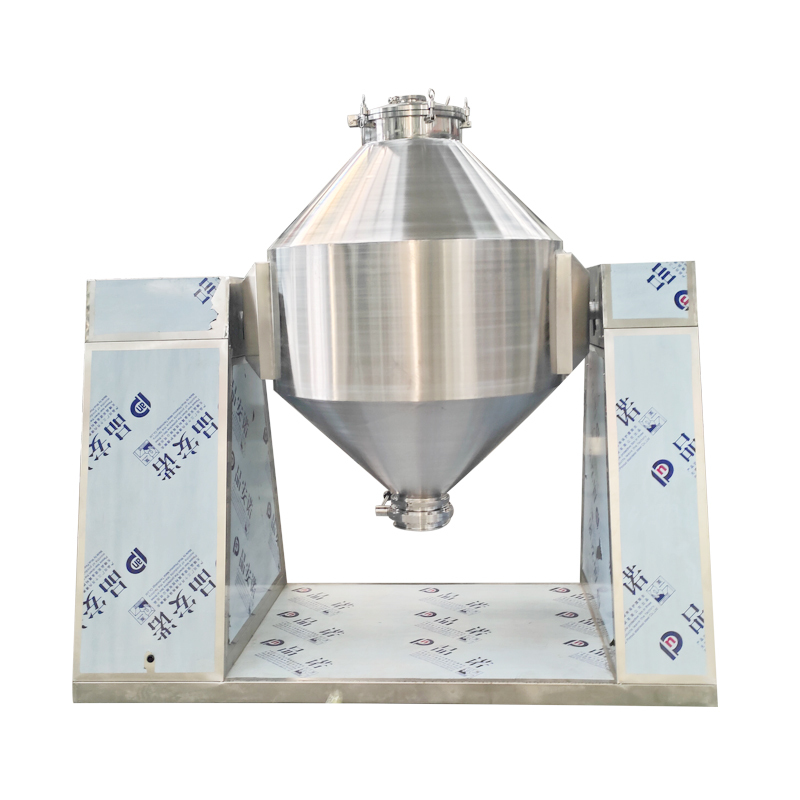

डबल कोन मिक्सर

उत्पाद विवरण

डबल कोन मिक्सर एक अत्यधिक कुशल पाउडर मिक्सिंग उपकरण है जिसमें डबल कोन के आकार का एक सीलबंद कंटेनर होता है। इसमें उच्च मिश्रण दक्षता, अच्छी एकरूपता, उपकरण के अंदर मिश्रण के लिए कोई मृत कोना नहीं होता है, और इसे साफ करना आसान होता है, जो सामग्री के अवशेषों को कम कर सकता है।

यह विभिन्न सामग्रियों के लिए व्यापक रूप से लागू होता है, जो मुक्त-प्रवाह वाले पाउडर और दानेदार सामग्रियों को संभालने में सक्षम है, और इसका उपयोग थोड़ी मात्रा में तरल पदार्थ मिलाने के लिए भी किया जा सकता है। यह आमतौर पर फार्मास्यूटिकल्स, खाद्य पदार्थों, रसायनों और निर्माण सामग्री जैसे उद्योगों में लागू होता है।

कार्य सिद्धांत

डबल-कोन मिक्सर का मुख्य कार्य सिद्धांत कंटेनर के घूर्णन के माध्यम से समान मिश्रण प्राप्त करना है: मुख्य डबल-शंक्वाकार बंद कंटेनर क्षैतिज केंद्र अक्ष के चारों ओर धीरे-धीरे घूमता है। इस प्रक्रिया के दौरान, कंटेनर के अंदर के पाउडर, कण और अन्य सामग्री, कंटेनर के आकार में परिवर्तन और घूर्णी बल की क्रिया के कारण, लगातार विघटित, आपस में जुड़ते, पलटते और कंटेनर के अंदर फिर से एकत्रित होते हैं। वे न केवल कंटेनर की आंतरिक दीवार के साथ एक गोलाकार गति में चलते हैं, बल्कि शंक्वाकार संक्रमण खंड में रेडियल पारस्परिक प्रवेश से भी गुजरते हैं। अंततः, सामग्रियों के विभिन्न घटक किसी भी मजबूर सरगर्मी घटकों का उपयोग किए बिना समान मिश्रण प्राप्त कर सकते हैं।

उत्पाद की विशेषताएं

1. बेहतर मिश्रण: उच्च एकरूपता, मृत कोनों के बिना डबल-कोन संरचना, बहु-घटक और अत्यधिक परिवर्तनशील पाउडर और दानेदार सामग्रियों के लिए उपयुक्त;

2. उच्च सुरक्षा: बंद कंटेनर डिजाइन, नमी अवशोषण, संदूषण और सामग्री के धूल रिसाव को रोकना, साफ आवश्यकताओं को पूरा करना;

3. आसान रखरखाव: जटिल मिश्रण घटकों के बिना सरल संरचना, आसान सफाई, कम अवशेष, कम पहनने वाले हिस्से और कम रखरखाव लागत;

4. व्यापक अनुप्रयोग: पाउडर और दानेदार सामग्री को संभाल सकता है, एक स्प्रे डिवाइस के साथ जो थोड़ी मात्रा में तरल भी मिला सकता है, कई उद्योगों को कवर करता है;

5. कम ऊर्जा की खपत: कंटेनर का कम गति से घूमना, कोमल सामग्री आंदोलन, कम ऊर्जा की खपत और सामग्री के गुणों को कम नुकसान।

अनुप्रयोग

1. मिश्रण की उच्च एकरूपता: शंक्वाकार संरचना सामग्री को स्वतंत्र रूप से प्रवाहित करने में सक्षम बनाती है, ठहराव को कम करती है, विशेष रूप से समान घनत्व वाले पाउडर/कणों के लिए उपयुक्त। मिश्रण की उच्च एकरूपता: शंक्वाकार संरचना सामग्री को स्वतंत्र रूप से प्रवाहित करने में सक्षम बनाती है, ठहराव को कम करती है, विशेष रूप से समान घनत्व वाले पाउडर/कणों के लिए उपयुक्त। मिश्रण की उच्च एकरूपता: शंक्वाकार संरचना सामग्री को स्वतंत्र रूप से प्रवाहित करने में सक्षम बनाती है, ठहराव को कम करती है, विशेष रूप से समान घनत्व वाले पाउडर/कणों के लिए उपयुक्त।

2. कम अवशिष्ट सामग्री: चिकनी आंतरिक दीवार + कोई मृत कोना डिजाइन नहीं, निर्वहन के बाद का अवशेष सरगर्मी पैडल वाले उपकरणों की तुलना में बहुत कम होता है, जो उच्च मूल्य वाली सामग्रियों के लिए उपयुक्त है।

3. अच्छा सीलिंग प्रदर्शन: पूरी तरह से संलग्न संरचना धूल रिसाव को कम करती है, दवा और खाद्य जैसे उद्योगों के स्वच्छ उत्पादन मानकों को पूरा करती है।

4. सरल रखरखाव: कोई जटिल घटक नहीं, कम विफलता दर, और पैडल या ब्लेड प्रकार के उपकरणों की तुलना में कम रखरखाव लागत।

5. कम ऊर्जा की खपत: गुरुत्वाकर्षण और घूर्णन द्वारा मिश्रित, उच्च-शक्ति मोटर की आवश्यकता नहीं है, और परिचालन लागत अधिक किफायती है।

6. व्यापक प्रयोज्यता: नाजुक सामग्रियों को कम नुकसान के साथ, सुखाने वाले पाउडर/कणों और थोड़ी मात्रा में तरल मिश्रण के लिए उपयुक्त।

उत्पाद पैरामीटर

| मॉडल |

W-300 |

W-500 |

W-1000 |

W-1500 |

W-2500 |

W-4000 |

W-6000 |

W-8000 |

|

उत्पादन क्षमता

(किलो/समय)

|

150 |

250 |

500 |

750 |

1250 |

2000 |

3000 |

4000 |

|

पूर्ण आयतन

(घन मीटर)

|

0.3 |

0.5 |

1 |

1.5 |

2.5 |

4 |

6 |

8 |

|

मिश्रण का समय

(मिनट)

|

4-8 |

4-8 |

6-12 |

6-12 |

6-12 |

6-15 |

6-15 |

6-15 |

|

मोटर शक्ति

(KW)

|

1.1 |

2.2 |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

| सिलेंडर की गति (RPM) |

15 |

15 |

12 |

12 |

12 |

10 |

10 |

10 |

|

आयाम

(L*W*H)

|

1680*650

*1600

|

2080*750

*1900

|

2150*850

*2100

|

2300*1600

*3100

|

2500*1000

*2450

|

2980*1580

*2800

|

3500*1800

*3000

|

3980*2000

*3200

|

| वज़न (किलो) |

310 |

550 |

800 |

950 |

1650 |

1880 |

2350 |

2680 |

उत्पादन लाइन आरेख

1. कार्यकर्ता धूल रहित बैग डंपिंग स्टेशन पर बैग छोड़ते हैं, क्योंकि मशीन में एक धूल कलेक्टर है, इसलिए धूल उड़ती है

2. छलनी मशीन गांठ या बड़े आकार की सामग्री को हटा देगी, केवल छोटे आकार की सामग्री को संदेश प्रणाली में प्रवाहित करने की अनुमति देती है

3. वैक्यूम कन्वेयर सामग्री को एक बफर हॉपर या एक स्टोरेज हॉपर में ले जाता है, मिश्रण की प्रतीक्षा करता है

4. जब आपको मिश्रण करने की आवश्यकता होती है, तो वैक्यूम फीडर काम करना शुरू कर देता है, सामग्री को हॉपर से डबल कोन मिक्सर में ले जाता है

5. मिश्रण के बाद, मिश्रित सामग्री को एक पैकिंग मशीन में ले जाया जाएगा, सेट वजन के अनुसार पैक किया जाएगा, और फिर बैग को सील कर दिया जाएगा

सिस्टम में, पूरी संदेश प्रक्रिया स्वच्छता और सुरक्षा सुनिश्चित करने के लिए सील की जाती है।

विस्तार प्रदर्शन

उत्पाद प्रदर्शन

पैकेजिंग और शिपिंग

हमें क्यों चुनें

हमारे बारे में

कंपनी प्रोफाइल

हम 13 वर्षों से स्क्रीनिंग और संदेश उपकरण के उत्पादन में विशेषज्ञता प्राप्त कर रहे हैं। चीन के कंपन स्क्रीन उद्योग में शीर्ष तीन। और हमने कई बड़ी कंपनियों के लिए मिलान और OEM किया है। दुनिया के शीर्ष कंपन स्क्रीन निर्माता, Sweco, USA सहित, हमने उसके चीन क्षेत्र के लिए OEM किया है। और हमारे उत्पादों को अक्सर ऑस्ट्रेलिया, थाईलैंड, इंडोनेशिया, न्यूजीलैंड और अन्य देशों में निर्यात किया जाता है।

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!