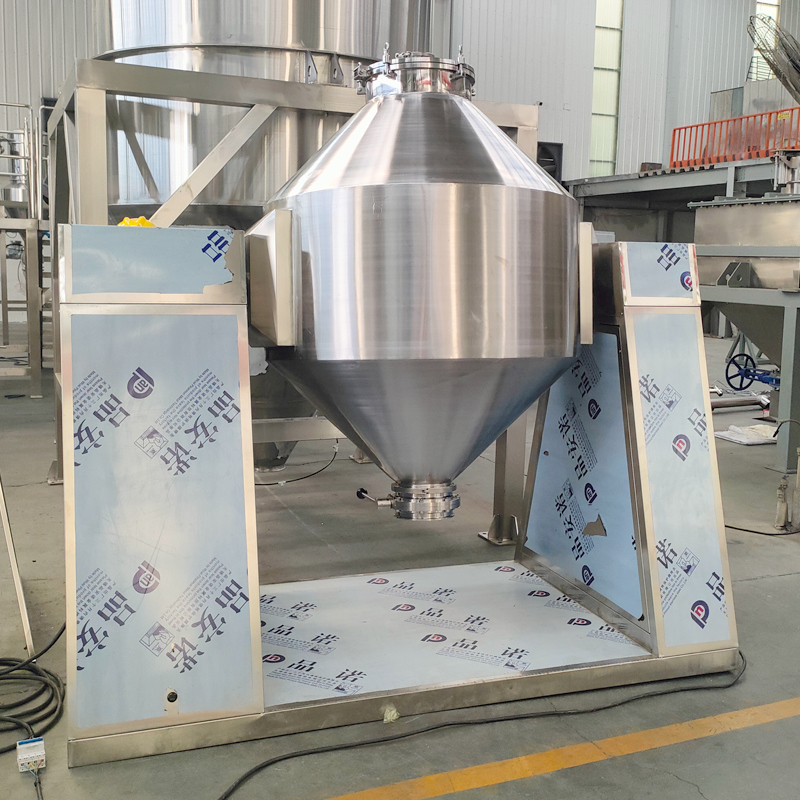

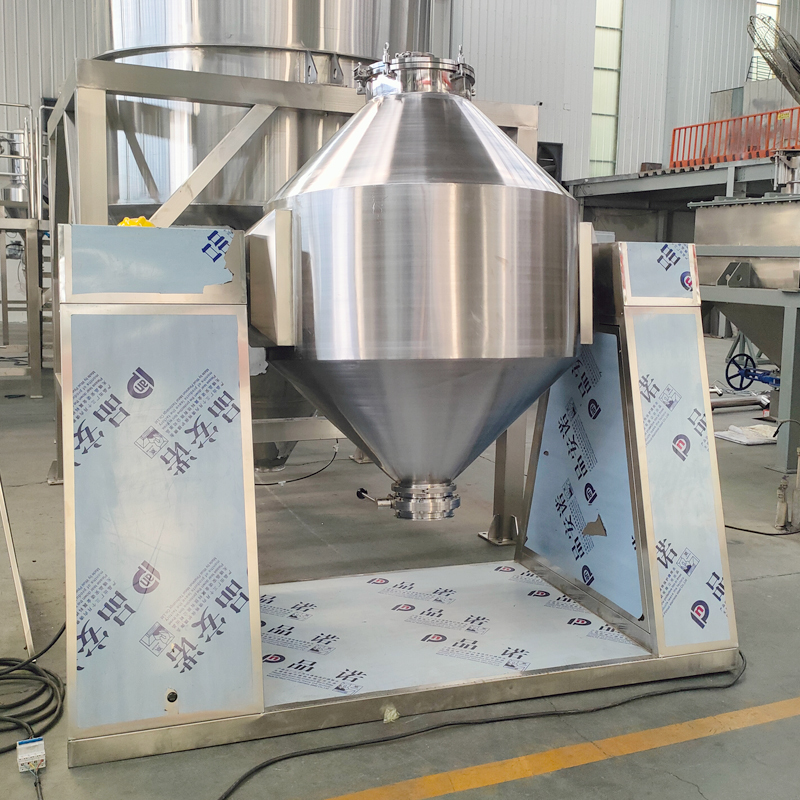

डबल कोन मिक्सर

उत्पाद का वर्णन

डबल-कोन मिक्सर एक कुशल पाउडर मिश्रण उपकरण है। इसका मुख्य शरीर एक डबल-कोनिकल सील कंटेनर है। इसमें उच्च मिश्रण दक्षता, कोई मिश्रण मृत क्षेत्र नहीं है,उत्कृष्ट सीलिंग प्रदर्शन (जो प्रभावी रूप से धूल प्रदूषण को रोक सकता है), और सुविधाजनक निर्वहन। यह पाउडर और अच्छी तरलता के साथ दानेदार सामग्रियों के लिए उपयुक्त है। यह व्यापक रूप से दवा, खाद्य, रसायन, निर्माण सामग्री, आदि के क्षेत्रों में लागू होता है,और विभिन्न उद्योगों में बैच उत्पादन में समान सामग्री मिश्रण की आवश्यकताओं को स्थिर रूप से पूरा कर सकता है.

कार्य सिद्धांत

डबल-कोन मिक्सर का मुख्य कामकाजी सिद्धांत कंटेनर की गति के माध्यम से सामग्रियों के जबरन अभिसरण और प्रसार मिश्रण को प्राप्त करना हैःडबल शंकु-सील कंटेनर क्षैतिज केंद्र अक्ष के चारों ओर घूमता हैघुमाव के दौरान सिलेंडर में सामग्री कंटेनर की दीवार के कारण एक निश्चित ऊंचाई तक उठती है, फिर गुरुत्वाकर्षण के कारण गिरती है और फैलती है।डबल शंकु संरचना सामग्री आगे और पीछे जाने के लिए मार्गदर्शन करता है और अंत और कंटेनर के बीच के बीच interweave, लगातार स्थिति आदान-प्रदान और पारस्परिक प्रवेश का अनुभव करते हैं।यह सामग्री की प्रारंभिक वितरण स्थिति को तोड़ता है और विभिन्न घटक पाउडर या कणों के समान मिश्रण का एहसास करता है.

उत्पाद की विशेषताएं

1उच्च मिश्रणः उच्च एकरूपता, डबल-कोन संरचना बिना मृत कोनों के, बहु-घटक और अत्यधिक परिवर्तनीय पाउडर और दानेदार सामग्रियों के लिए उपयुक्त;

2उच्च सुरक्षाः बंद कंटेनर डिजाइन, नमी अवशोषण, प्रदूषण और धूल लीक सामग्री को रोकने, स्वच्छता आवश्यकताओं को पूरा;

3आसान रखरखाव: जटिल मिश्रण घटकों के बिना सरल संरचना, आसान सफाई, कम अवशेष, कम पहनने वाले भाग और कम रखरखाव लागत;

4व्यापक अनुप्रयोगः पाउडर और दानेदार सामग्रियों को संभाल सकता है, एक स्प्रे डिवाइस के साथ जो एक छोटी मात्रा में तरल भी मिला सकता है, कई उद्योगों को कवर कर सकता है;

5कम ऊर्जा की खपतः कंटेनर की कम गति से घूर्णन, सामग्री की कोमल गति, कम ऊर्जा की खपत और सामग्री गुणों को कम नुकसान।

आवेदन

1समान रूप से मिश्रण करें: कोई मृत कोने नहीं। डबल-कोन संरचना सामग्री को पूरी तरह से मिश्रण करने में मदद करती है, उच्च एकरूपता के साथ, पाउडर और दानेदार सामग्री के लिए उपयुक्त है;

2. अच्छी तरह से सीलः सील कंटेनर डिजाइन धूल संदूषण और सामग्री रिसाव को रोकता है, स्वच्छ उद्योग की आवश्यकताओं को पूरा करता है;

3संचालित करने में आसान: सरल संरचना, त्वरित डिस्चार्ज, कम अवशेष, दैनिक रखरखाव के लिए जटिल असेंबलिंग की आवश्यकता नहीं;

4अनुप्रयोगों की विस्तृत श्रृंखलाः विभिन्न उद्योगों की सामान्य और विशेष प्रक्रिया आवश्यकताओं के लिए उपयुक्त तापमान नियंत्रण और वैक्यूम प्रणालियों से सुसज्जित किया जा सकता है;

5कम हानिः उच्च गति से घुमाने वाले घटकों का अभाव, कम सामग्री का पहनना, स्थिर गुण, कम उपकरण संचालन शोर, लंबी सेवा जीवन।

उत्पाद पैरामीटर

| मॉडल |

W-300 |

W-500 |

W-1000 |

W-1500 |

W-2500 |

W-4000 |

W-6000 |

W-8000 |

|

उत्पादन क्षमता

(किग्रा/समय)

|

150 |

250 |

500 |

750 |

1250 |

2000 |

3000 |

4000 |

|

पूर्ण मात्रा

(घन मीटर)

|

0.3 |

0.5 |

1 |

1.5 |

2.5 |

4 |

6 |

8 |

|

मिश्रण का समय

(मिनट)

|

चार से आठ |

चार से आठ |

6-12 |

6-12 |

6-12 |

6-15 |

6-15 |

6-15 |

|

मोटर शक्ति

(किलोवाट)

|

1.1 |

2.2 |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

| सिलेंडर की गति (आरपीएम) |

15 |

15 |

12 |

12 |

12 |

10 |

10 |

10 |

|

आयाम

(L*W*H)

|

1680*650

*1600

|

2080*750

*1900

|

2150*850

*2100

|

2300*1600

*3100

|

2500*1000

*2450

|

2980*1580

*2800

|

3500*1800

*3000

|

3980*2000

*3200

|

| वजन (किलो) |

310 |

550 |

800 |

950 |

1650 |

1880 |

2350 |

2680 |

उत्पादन लाइन आरेख

1. श्रमिक धूल मुक्त बैग डंपिंग स्टेशन पर बैग जारी करते हैं, क्योंकि मशीन में धूल कलेक्टर है, इसलिए धूल उड़ती है

2. सीवे मशीन गांठ या बड़े आकार की सामग्री को हटा देगी, केवल छोटे आकार की सामग्री को कन्वेयर सिस्टम में बहने की अनुमति देगी

3वैक्यूम कन्वेयर सामग्री को एक बफर होपर या भंडारण होपर में ले जाता है, मिश्रण की प्रतीक्षा करता है

4. जब आप मिश्रण करने की जरूरत है, वैक्यूम फीडर काम शुरू होता है, डबल शंकु मिक्सर के लिए हॉपर से सामग्री परिवहन

5मिश्रण के बाद मिश्रित सामग्री को पैकिंग मशीन में ले जाया जाता है, निर्धारित वजन के अनुसार पैक किया जाता है और फिर बैग को सील कर दिया जाता है।

इस प्रणाली में स्वच्छता और सुरक्षा सुनिश्चित करने के लिए परिवहन की पूरी प्रक्रिया को सील कर दिया गया है।

विवरण प्रदर्शित करना

उत्पाद प्रदर्शन

पैकेजिंग और शिपिंग

हमें क्यों चुनें?

हमारे बारे में

कंपनी प्रोफ़ाइल

हम 13 साल के लिए स्क्रीनिंग और उपकरण ले जाने के उत्पादन में विशेषज्ञता प्राप्त है। चीन के कंपन स्क्रीन उद्योग शीर्ष तीन। और हम कई बड़ी कंपनियों के लिए मिलान और OEM किया है।दुनिया के शीर्ष कंपन स्क्रीन निर्माता सहित, Sweco, संयुक्त राज्य अमेरिका, हम अपने चीन क्षेत्र के लिए OEM है। और हमारे उत्पादों को अक्सर ऑस्ट्रेलिया, थाईलैंड, इंडोनेशिया, न्यूजीलैंड और अन्य देशों को निर्यात कर रहे हैं।

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!